When people hear the word “asbestos,” it can feel intimidating—and for good reason. Asbestos-Containing Materials (ACMs) must be handled carefully, even when they’re considered non-friable. The key is experience, preparation, and strict control throughout the entire process. At EAS Environmental, we provide asbestos abatement services throughout both South Carolina and Georgia. We use the information we are given by the Client to come up with a stellar Scope of Work including engineering controls, removal/abatement protocols, and disposal methods. Our goal is to help you understand how professional abatement is planned, executed, and verified, so that you can make the right decision when deciding who to hire as an abatement contractor.

Abstract:

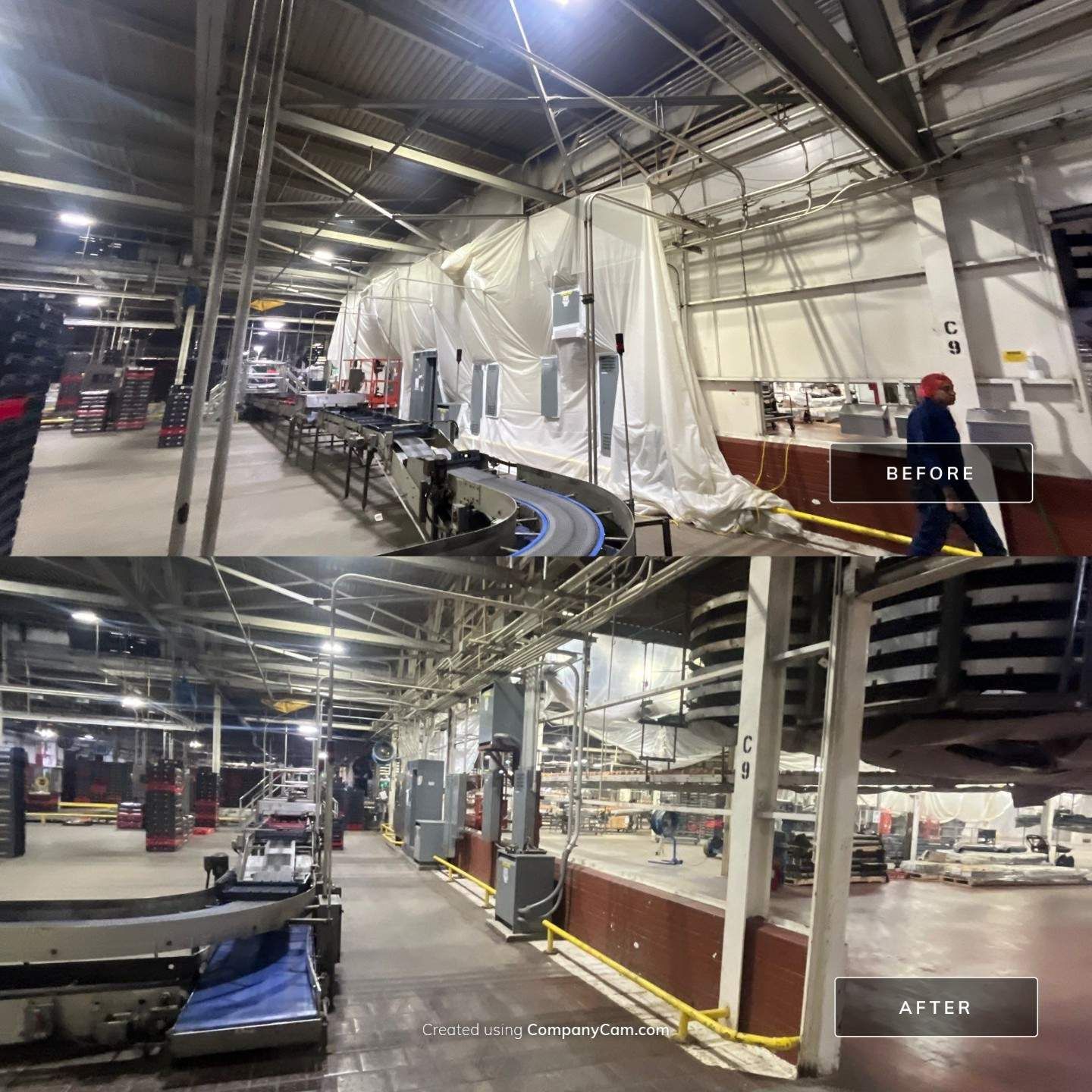

EAS Environmental completed a Class II, non-friable Category II asbestos abatement project at a commercial facility in Savannah, GA, involving the controlled removal of asbestos-containing Transite wall panels. In this case study, we will outline the process of how our team prepared the regulated area, used engineering controls like containment barriers and HEPA filtration, the methods we used in order to remove panels while intact, packaged waste correctly for disposal, and followed documentation and inspection procedures to ensure a safe, compliant close-out. This article emphasizes the importance of the amount of care that these types of abatement projects require.

The Situation: Transite Panels Require Safe, Controlled Removal

Transite panels are cement-based materials that often contain asbestos. While they are considered non-friable (meaning fibers aren’t easily released when intact), improper disturbance can create risk to everyone involved. Cutting, breaking, or aggressive removal methods can cause the material to become friable, increasing the potential for airborne fiber release and exposure. For this reason, controlled handling and appropriate work practices are essential during abatement.

Our Solution: Non-Friable Asbestos Abatement

After third-party samples and laboratory results confirmed the presence of asbestos in the Transite panels, our team developed a Scope of Work to safely and effectively abate the ACMs.

Step 1: Understanding the Material and the Space

In this case, the Transite panels were classified as non-friable, indicating the material remains stable under normal conditions. That classification matters — but it doesn’t mean the work can be rushed. Before any of our crews were mobilized, our team:

- Reviewed the third-party sampling report and building layout.

- Identified the locations of the transite panels.

- Confirmed regulatory requirements under OSHA and EPA standards.

- Developed a detailed Scope of Work & Work Plan that was specific to this site.

Step 2: Preparing the Work Area

Once we had a clear Work Plan, and our crews had mobilized to the site, the next step was getting the Work Area containment set up properly. This part of the process doesn’t often get much attention — but it is easily one of the most important steps. In order to ensure proper containment, our crews needed to:

- Established a regulated asbestos work area with warning signage.

- Shut off and isolated HVAC systems to prevent fiber migration.

- Installed poly curtain walls and floor protection.

- Set up air filtration devices and HEPA vacuums.

- Ensured a certified supervisor (competent person) was on site at all times.

The goal here is simple: control the environment before the work begins.

Step 3: Careful, Controlled Panel Removal

After all of our containment was in place, our technicians suited up in full PPE and began the abatement/removal process. Because the panels were non-friable, our approach focused on keeping the material intact upon removal. Work activities were performed using careful, controlled methods to minimize disturbance and prevent unnecessary breakage:

- Transite panels were adequately wetted using surfactants.

- Fasteners were carefully disconnected.

- Panels were removed whole, not broken apart.

- Materials remained inside the containment until prepped for disposal.

Every move was deliberate — slow, steady, and controlled. No shortcuts!

Step 4: Cleanup, Encapsulation, and Waste Handling

Once the panels were removed, the work was not completed yet. Even with non-friable abatement methods, it is extremely important that our crews make certain that no residuals are left behind:

- Cleaned the work area thoroughly using HEPA vacuums.

- Removed any residual material.

- Applied a lockdown fiber encapsulant to affected surfaces.

- Packaged all asbestos-containing materials in lined containers or double-wrapped poly.

- All waste was properly labeled, logged, and transferred to a secured EAS Environmental work trailer for approved disposal.

Step 5: Final Inspection and Close-Out

Before the site could be cleared, there are a multitude of compliance standards and clearances that need to pass:

- A detailed visual inspection by a competent person (site supervisor).

- Coordination with air monitoring professionals for both air sampling & visual clearances.

- Final jobsite cleanup.

- Completion of all required documentation and waste manifests.

Only after everything met safety and compliance standards did we consider the project complete.

Why This Approach Matters

Asbestos abatement isn’t just about removing the material — it’s about protecting people. Our job is to make sure building occupants, workers, and the surrounding environment remain safe throughout the entire process.

This project reflects how we approach every abatement job:

✔ Detailed planning

✔ Trained & certified crews

✔ Strict safety controls & removal methods

✔ Clear documentation

✔ No cutting corners

A Team You Can Trust

We’re proud of the professionalism our team brought to this project, and we are extremely grateful to the company for trusting us with this important work. At EAS Environmental, we believe doing the job right is the only way to do it — especially when health and safety are involved.

Need Help with Asbestos or Environmental Concerns?

If your building contains asbestos-containing materials — or if you’re not sure — early assessment and proper planning are critical.

📞

Call EAS Environmental: 843-977-EASE

🌐

Visit: www.easenvironmental.com

We’re here to help you navigate complex environmental challenges safely, responsibly, and with confidence.

Contact EAS Environmental Today!

EAS Environmental will do everything we can to ensure your experience with us is excellent.

Request A FREE Estimate

Request a Free Estimate Form

Checkout Recent Post

Got a Question? We’re Here to Help.

You can arrange an appointment or make an enquiry by phone or email, orget in touch to us via our contact form.